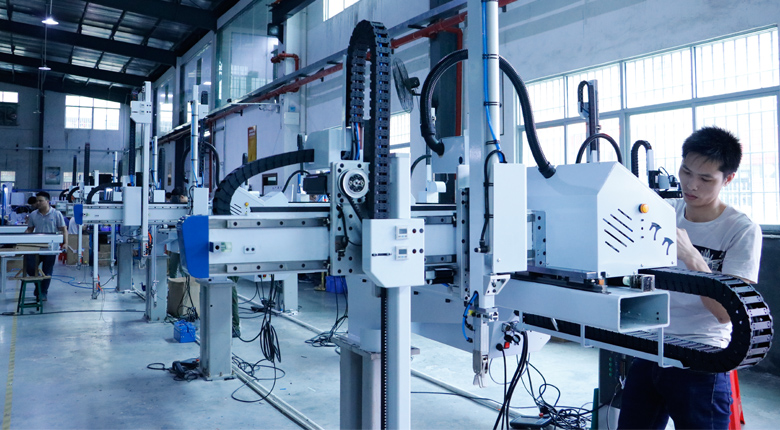

Among plastic molded products, those with thinner constructions that are used in medical equipment, tableware and kitchen utensils, optical disks and other fields are mass produced. There is a strong call in these fields for higher production efficiency. For that reason, using take out robot in molding processes to shorten total cycle times using higher-speed operation has become a primary focus of interest. A tiny difference of a fraction of a second in the cycle time can mean a huge difference in your overall productivity of the plant. Another demand is for take -out robot that can repeat the same operation many thousands of times in succession without an error. Take out robot that can meet these exacting demands continuously, at ultra-high speeds.

With the explosive growth taking place in the information equipment market, a world record of 0.069 seconds has been achieved in the field of mass-produced plastic cutlery and other optical disks. It follows that take out robot is so important to every factory. The factory use take out robot not only reduce cost, but also can create wealth. That achievement has been highly acclaimed by the industry worldwide.